We support complete end-to-end packaging customization solutions, helping all private label importers and online e-commerce brands to create their own unique packaging and establish brand effect.

Hualian Glass and Ruisheng Glass are a guarantee of premium quality combined with cost-effectiveness and short delivery times.

In 2022, Hualian Glass and Ruisheng Glass signed a strategic cooperation agreement to jointly establish TomBottle, a high-end Liquor bottle custom production brand. As one of the strongest manufacturers in the industry, we are committed to customers’ high-end Liquor bottle customization business.

Hualian Glass Bottle Manufacturers In China, We has been designing and manufacturing glass bottles and jars, and we’re still leading the way when it comes to quality, flexibility and innovation. We have a wide range of general sale glass containers for the food, pharmaceutical and beverage markets, many available there are many glass bottles and jars stock.

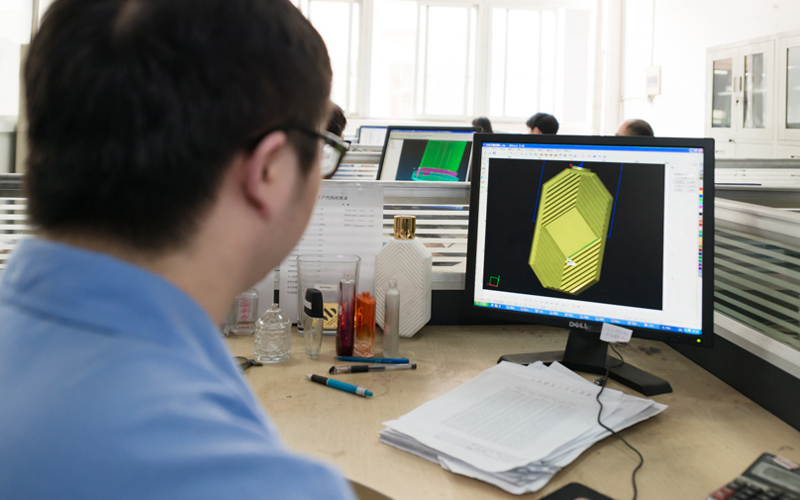

We also have our own in-house glass bottle design team offering a complete service for your Custom glass packaging, from initial concept to manufacture and decoration.

Hualian glass bottle factory is Glass Bottle Manufacturers in China, Provide you with custom glass bottle with a low threshold. Custom glass bottle design can highlight your brand. We are very excited to turn your unique ideas into real products

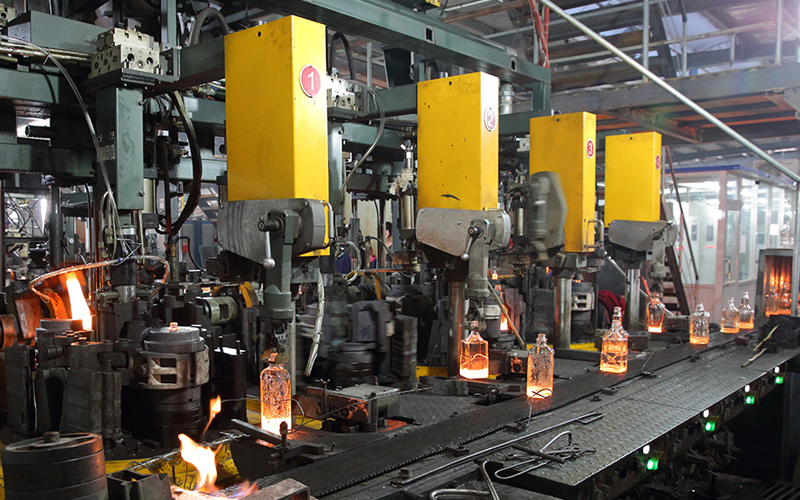

As one of the largest glass bottle manufacturers in China, We has invested and controlled the construction of 6 kilns, which can produce glass products of various materials such as brown glass, green glass, transparent glass, and super flint glass.

The production workshop can be selected according to the customer’s requirements to solve the problem of customer order production.

Our total annual output is 400,000 tons of glass.

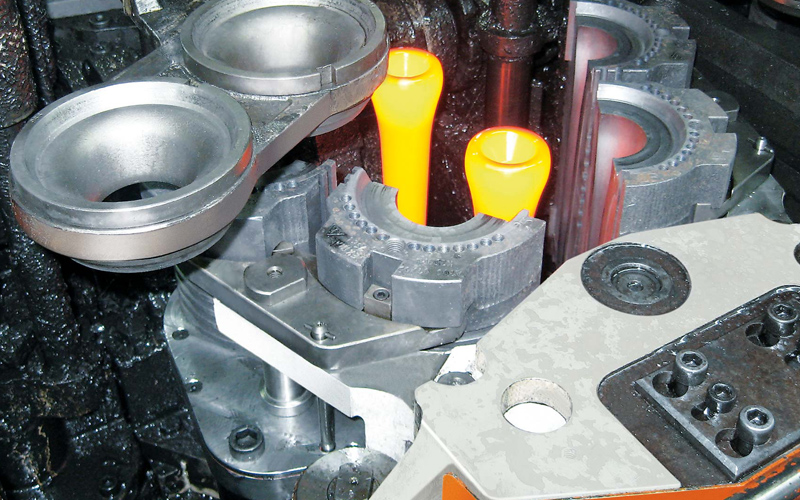

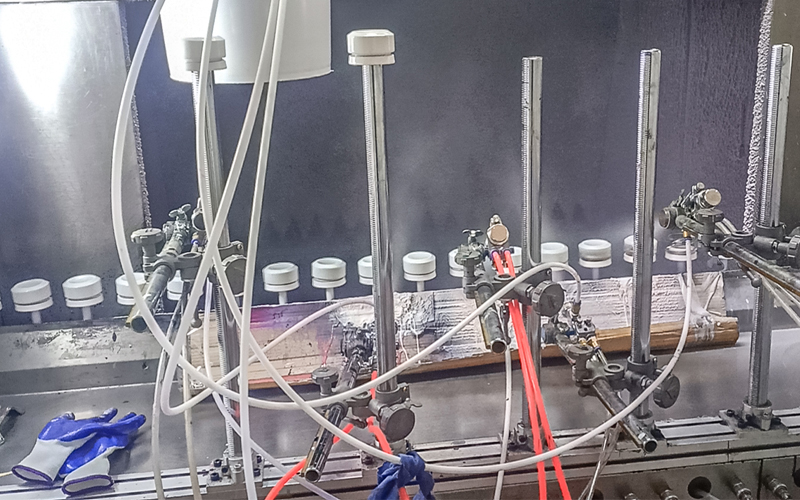

We all use the most advanced domestic Sanjin bottle making machines and the most advanced multi-weight computerized servo feeders.

SANJIN Bottle making machine has more material drop and group number, higher precision machining and assembly process ensures the reliability and stability of the machine. The multi-weight computer servo feeder can complete the production of multiple weights on the same machine. Each equipment can complete the feeding span of the maximum weight of 200g, and the accuracy is controlled within plus or minus 5g. It can perfectly solve the request of many customers with low MOQ.

Tom Bottle has an independent mold design team, including 2 senior engineers with more than 35 years of work experience. There are 5 outstanding designers, all of whom have postgraduate degrees and have worked for more than 5 years. 14 excellent CNC operators.

Tom Bottle independent mold machining center has the most advanced 5-axis simultaneous machining center in China, CNC lathes and other related machinery. The production and processing of molds can be completed quickly and efficiently.

We would love to hear about your project and discuss how we can help. To schedule a meeting with our team, simply fill out the form in this section.

©2024. Tom Bottle. All Rights Reserved.